When developing pharmaceutical products, selecting the right sterilization method is critical to ensuring product safety, regulatory compliance, and cost-effectiveness. Two primary methods exist: terminal sterilization and aseptic filling. Each approach has distinct advantages and challenges, making it essential to choose wisely based on your product’s characteristics, stability, and regulatory requirements.

In this article, we will define terminal sterilization and aseptic filling, highlight their key differences, and explain why this decision is so crucial for pharmaceutical companies.

What is Terminal Sterilization?

Terminal sterilization is the process of sterilizing a product in its final sealed container. This means that the product undergoes sterilization at the last stage of manufacturing, ensuring the highest level of sterility assurance.

Common Terminal Sterilization Methods

- Heat (Steam or Dry Heat): The most effective and widely used method, especially for products that can withstand high temperatures.

- Irradiation (Gamma or Electron Beam): Used for heat-sensitive products, such as biologics or plastic packaging.

- Chemical (Ethylene Oxide or Hydrogen Peroxide): Applied to products that cannot tolerate heat or radiation.

Advantages of Terminal Sterilization

- Higher Sterility Assurance Level (SAL): Since sterilization happens at the final stage, the risk of microbial contamination is minimized.

- Regulatory Preference: Regulatory bodies like the FDA and EMA prefer terminal sterilization whenever possible.

- Cost-Effectiveness: Typically less expensive than aseptic filling due to lower manufacturing complexity.

- Scalability: Easier to scale production since the sterilization process is independent of handling and filling conditions.

Challenges of Terminal Sterilization

- Not Suitable for All Products: Some biologics, vaccines, and complex formulations degrade under high heat, radiation, or chemicals.

- Potential Product Alteration: Terminal sterilization can impact product integrity, especially for sensitive drugs.

Where We Specialize in Terminal Sterilization

Our Halden facility (Norway) is dedicated to terminal sterilization, offering expertise in optimizing sterilization parameters while ensuring product quality.

What is Aseptic Filling?

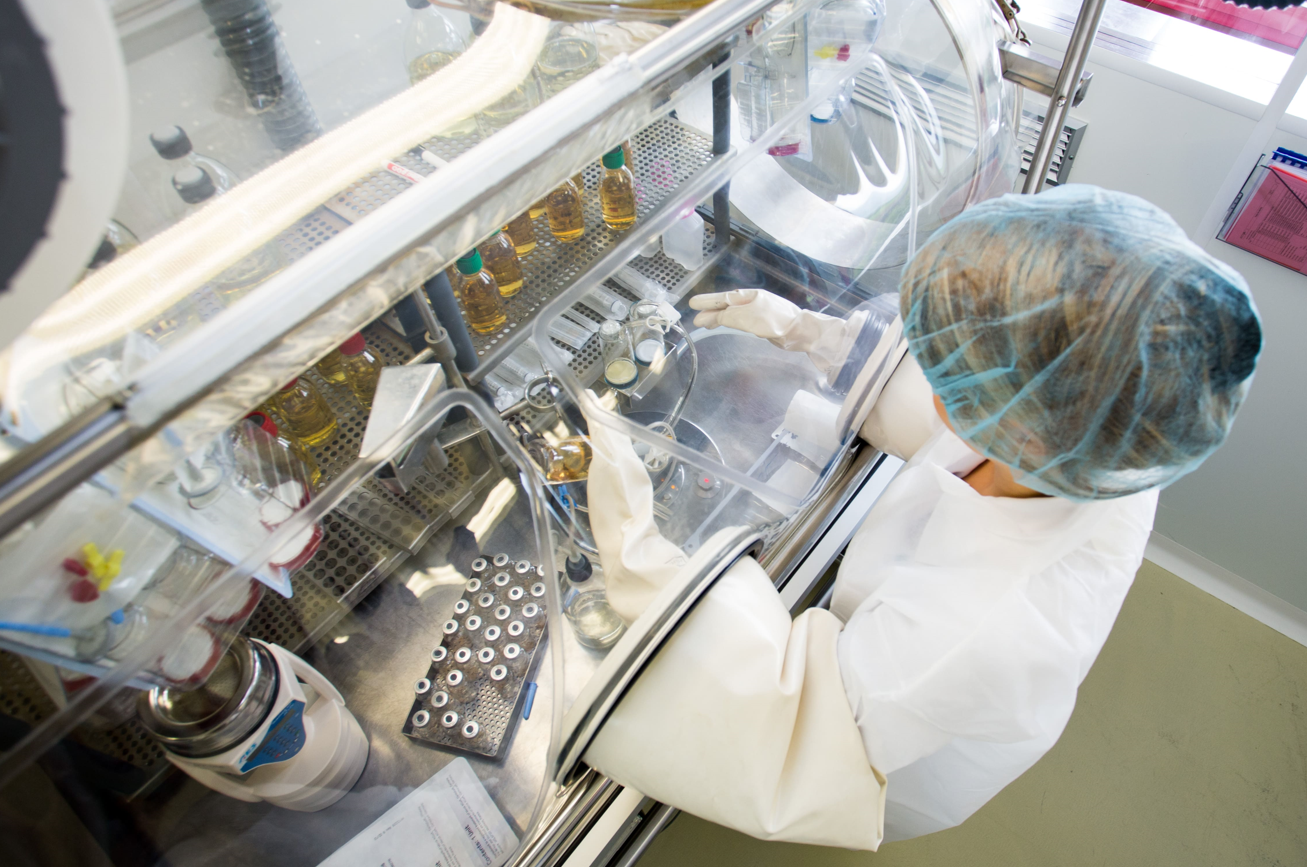

Aseptic filling is a process in which the drug product, container, and closure are sterilized separately before filling. The sterile product is then transferred into pre-sterilized containers under strictly controlled cleanroom conditions.

Steps in Aseptic Filling

- Sterilization of Components: The product, vials, and closures undergo separate sterilization.

- Aseptic Assembly: All components are brought together in an aseptic environment.

- Filling & Sealing: The sterile product is filled into containers within a classified cleanroom using isolators or restricted-access barrier systems (RABS).

- Final Packaging: The product is sealed and packaged under aseptic conditions to maintain sterility.

Advantages of Aseptic Filling

- Essential for Heat-Sensitive Products: Ideal for biologics, monoclonal antibodies, and vaccines that cannot tolerate terminal sterilization.

- Preserves Product Integrity: Maintains the stability and efficacy of delicate formulations.

- Suitable for Complex Drug Products: Necessary for injectable drugs, ophthalmic solutions, and advanced therapies.

Challenges of Aseptic Filling

- Higher Contamination Risk: Requires extensive environmental controls, skilled personnel, and validation procedures.

- Regulatory Complexity: Compliance with GMP and sterility assurance requires rigorous quality control.

- Higher Costs: More expensive due to specialized equipment, personnel training, and extensive process monitoring.

Where We Specialize in Aseptic Filling

Our Livron (France) and Jura (Switzerland) facilities are dedicated to aseptic filling, ensuring compliance with the highest sterile manufacturing standards for sensitive pharmaceutical products.

Terminal Sterilization vs Aseptic Filling: Key Differences

| Aspect | Terminal Sterilization | Aseptic Filling |

|---|---|---|

| Sterilization Stage | After final packaging | Before filling |

| Best for | Heat-stable drugs (e.g., small molecule injectables) | Heat-sensitive drugs (e.g., biologics, vaccines) |

| Sterility Assurance Level (SAL) | Higher (10⁻⁶) | Lower (relies on aseptic techniques) |

| Regulatory Preference | Preferred when feasible | Accepted when terminal sterilization isn’t an option |

| Process Complexity | Simpler, fewer contamination risks | More complex, requires extensive control |

| Cost | Lower | Higher |

How to Choose the Right Method?

- If your product can tolerate heat, radiation, or chemical sterilization, terminal sterilization is the better choice due to its higher sterility assurance and lower cost.

- If your product is sensitive to heat or sterilization agents, aseptic filling is necessary to maintain its integrity.

- Regulatory agencies prefer terminal sterilization, so if aseptic filling is chosen, it must be justified with scientific data.

Choosing between terminal sterilization and aseptic filling is a critical decision that impacts sterility, regulatory compliance, and product stability. While terminal sterilization is the gold standard for sterility assurance and cost-effectiveness, aseptic filling is indispensable for sensitive formulations that cannot withstand harsh sterilization conditions.

At our Halden facility, we specialize in terminal sterilization, while our Livron and Jura facilities focus on aseptic filling—ensuring that your pharmaceutical products are manufactured with the highest sterility standards.

If you are unsure about which method is best for your product, consulting with experts early in the development process is crucial to avoid regulatory hurdles and ensure patient safety.

Discover our facility: Halden

Discover our facility: Livron

Discover our facility: Jura

FAQs About Terminal Sterilization vs Aseptic Filling

What is the difference between sterilization and aseptic processing?

Sterilization eliminates all microbial life from a product or surface, while aseptic processing ensures that already sterilized components remain sterile during handling and filling.

Why is terminal sterilization preferred?

Regulatory agencies prefer terminal sterilization because it provides a higher sterility assurance level (SAL of 10⁻⁶), is easier to validate, and reduces contamination risks.

What is the terminal method of sterilization?

Terminal sterilization methods include heat (steam or dry heat), irradiation (gamma or e-beam), and chemical sterilization (ethylene oxide or hydrogen peroxide), applied after final packaging.

What is the difference between aseptic, sterile, and clean?

Aseptic refers to a process that prevents contamination of a sterile product.

Sterile means free from all viable microorganisms.

Clean refers to controlled environments that reduce, but do not eliminate, contamination.