In the ever-evolving landscape of pharmaceutical manufacturing, technologies that enhance efficiency, sterility, and product safety are in high demand. One such game-changing technology is Blow Fill Seal (BFS). Our recently acquired facility in Halden, Norway, is a testament to this advanced manufacturing technology. It is one of the most important sterile manufacturing facilities in Northern Europe, specialising in the production of plastic ampoules and vials using BFS technology.

What is Blow Fill Seal Technology?

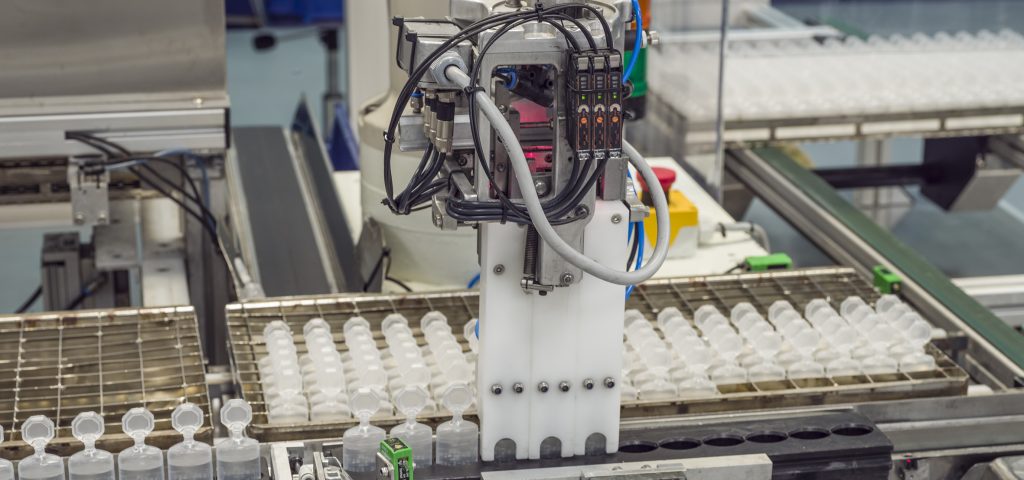

Blow Fill Seal (BFS) technology is an automated manufacturing process by which plastic containers are blow-molded, filled with a pharmaceutical product, and then sealed in a single, continuous operation. The process is completed without human intervention, which significantly reduces the risk of contamination and ensures a high degree of sterility.

How Blow Fill Seal Works

- Blow: A plastic preform is heated and then blown into a mold to create a container.

- Fill: The pharmaceutical product is filled into the newly formed container.

- Seal: The container is immediately sealed, creating an airtight and sterile product.

This streamlined process not only minimizes the possibility of contamination but also increases manufacturing speed and efficiency.

Applications and Benefits of BFS Technology

Versatility

Blow Fill Seal (BFS) technology is utilized in the production of various pharmaceutical products, including:

- Plastic Ampoules: Used for single-dose liquids like eye drops and inhalation solutions.

- Vials: Suitable for vaccine packaging and other injectable drugs.

Key Advantages

- Sterility Assurance: Since the entire process is automated and occurs in a closed system, the risk of contamination is significantly reduced.

- Cost-Effectiveness: BFS reduces the need for multiple packaging steps, cutting down on labor costs, and speeding up production times.

- Flexibility: The technology can be adapted to create various container shapes and sizes, making it highly versatile for different pharmaceutical formulations.

- Environmental Friendly: BFS packaging often uses less material and generates less waste compared to traditional methods.

Efficiency and Sterility

Blow Fill Seal (BFS) technology stands out for its ability to enhance both efficiency and sterility in pharmaceutical manufacturing. By integrating the forming, filling, and sealing processes into a single automated system, BFS minimizes contamination risks common in multi-step processes. This ensures the production of sterile, safe pharmaceutical products, which is crucial for patient safety and compliance with regulatory standards.

Our Facility in Halden, Norway

Our Halden facility in Norway is one of the largest and most advanced sterile production facilities in Northern Europe. Specializing in the manufacturing of plastic ampoules, and vials using BFS technology, the facility is equipped to handle a wide range of production needs.

Let’s take a closer look at what makes our Halden facility so special.

Advanced BFS Production Capabilities

- BFS Ampoules from 5 ml to 30 ml: Capable of producing small volume ampoules, ideal for single-dose applications like eye drops and inhalation solutions.

- BFS Vials from 10 ml to 100 ml: Our capabilities extend to larger vial sizes, suitable for vaccines and other critical injectable drugs.

- Large Batch Sizes up to 5,000 Liters: We can handle significant volumes, ensuring we meet the high demands of the pharmaceutical industry without compromising on quality or efficiency.

Emphasis on Quality and Compliance

We continuously strive for excellence in our operations, implementing stringent quality control measures. Our facility adheres to global standards and best practices, ensuring that each product leaving our plant is of the highest quality. This includes:

- Automated, Closed System Processes: Minimizes human intervention and contamination.

- Regularly Updated Protocols: Keeps our methods and practices in line with the latest regulatory guidelines and technological advancements.

Comprehensive Services

Beyond just manufacturing, our Halden facility offers a wide range of services that cover every aspect of the production process. From development and formulation to packaging and distribution, we provide end-to-end solutions that cater to the diverse needs of our partners.

Blow Fill Seal technology is indeed revolutionizing the pharmaceutical industry, offering unmatched benefits in terms of sterility, efficiency, and versatility. Our facility in Halden, Norway, is at the forefront of this innovation, providing top-notch BFS manufacturing capabilities to meet diverse pharmaceutical needs. By leveraging Blow Fill Seal technology, pharmaceutical companies can ensure better product quality, safety, and compliance with stringent global standards.

FAQs about Blow Fill Seal

What is BFS and FFS?

BFS (Blow Fill Seal) is a method used in the pharmaceutical industry for making and filling aseptic liquid containers. FFS (Form Fill Seal) is similar but more commonly used for packaging food and consumer goods, creating, filling, and sealing packages in a single process.

What are Blow-Fill-Seal pharmaceutical products?

Blow-Fill-Seal pharmaceutical products refer to containers such as ampoules and vials created and filled with liquid medication using BFS technology to ensure sterility and safety.

What is FFS in pharma?

In the pharmaceutical industry, FFS (Form Fill Seal) is a technique whereby plastic films are formed into containers, filled with pharmaceutical products, and then sealed to maintain sterility and extend shelf life.

Why is Blow Fill Seal better for sterile products?

Blow Fill Seal technology is superior for sterile products because it significantly reduces the risk of contamination by automating the entire process within a sterile environment. This minimizes human intervention and enhances product safety.

What products can be manufactured using Blow Fill Seal?

Blow Fill Seal technology is versatile and can be used to manufacture a range of sterile products, including ophthalmic solutions, respiratory products, and other liquid medications.

How does Blow Fill Seal improve production efficiency?

Blow Fill Seal improves production efficiency by integrating the blow molding, filling, and sealing processes into a single operation. This reduces production time, minimizes labor costs, and increases overall manufacturing throughput.

Are there any limitations to Blow Fill Seal technology?

While BFS technology offers numerous advantages, it may not be suitable for products requiring complex packaging shapes or certain solid dosage forms. It is primarily used for liquid and semi-liquid pharmaceuticals requiring high sterility standards.