In the evolving landscape of the pharmaceutical industry, maintaining high-quality standards is critical for success. At the core of this effort is the Pharmaceutical Quality System (PQS), which ensures that products not only meet regulatory requirements but also serve their intended purpose without compromising patient safety. For Contract Development and Manufacturing Organizations (CDMOs), understanding and implementing robust pharmaceutical quality systems is essential to attract and retain clients in this highly competitive market.

Understanding the Pharmaceutical Quality System (PQS)

What is Pharmaceutical Quality System?

The Pharmaceutical Quality System (PQS), formerly called Quality Management System (QMS), is a comprehensive collection of policies, processes, and procedures designed to ensure and maintain uniform and high quality in the production of pharmaceutical products. In the pharmaceutical industry, a QMS is not just a regulatory requirement but a cornerstone of operational excellence. Implementing a robust QMS is crucial for ensuring the quality, safety, and efficacy of pharmaceutical products.

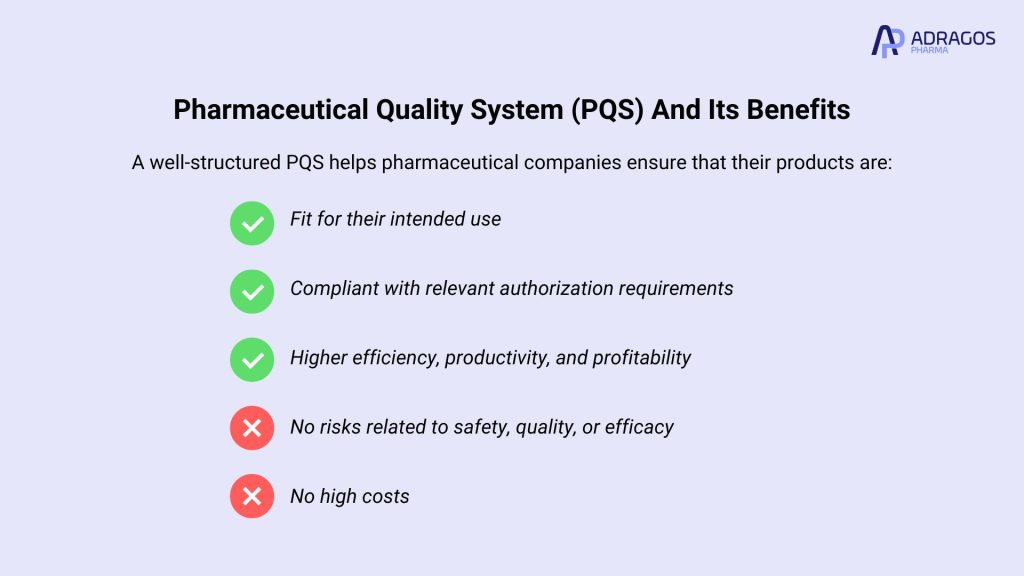

A well-structured QMS enables companies to streamline their quality processes, improve efficiency and productivity, reduce costs, and ultimately enhance profitability. By standardizing procedures and fostering a culture of continuous improvement, a QMS helps pharmaceutical companies navigate the complexities of regulatory compliance while maintaining high standards of product quality. This system is essential for building trust with clients and regulatory bodies, ensuring that every product released into the market meets stringent quality criteria.

The Importance of PQS in Pharmaceuticals

For CDMOs, a robust PQS is not just a regulatory necessity; it is also a significant value proposition. Clients seek partners who can demonstrate a commitment to quality, efficiency, and compliance. A strong PQS enhances a CDMO’s reputation and helps in building trust with pharmaceutical companies looking to outsource their development and manufacturing needs.

Regulatory Framework and Standards

Compliance with established regulatory frameworks is crucial for CDMOs. Extensive regulatory oversight ensures that CDMOs comply with established regulatory frameworks. Two significant standards that inform the pharmaceutical quality systems are ISO 9001:2015 and ICH Q10.

ISO 9001:2015

ISO (International Organization for Standardization) is an independent, non-governmental international organization that develops and publishes a wide range of standards across various industries. The current standard for Quality Management Systems (QMS) is ISO 9001:2015. This standard provides a framework for establishing and maintaining a quality management system, ensuring consistent quality across processes.

ICH Q10

ICH (International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use) is a unique project that brings together the regulatory authorities and pharmaceutical industry to discuss scientific and technical aspects of drug registration. The guidelines developed by ICH aim to ensure that safe, effective, and high-quality medicines are developed and registered efficiently.

In particular, the ICH Q10 guideline focuses specifically on the pharmaceutical industry, providing a comprehensive approach to quality management throughout the whole pharmaceutical product lifecycle, from product development to commercialization. It integrates various quality elements to enhance efficiency and compliance. Key components include:

- Process performance and product quality monitoring

- Management review of quality processes

- Quality risk management (QRM) strategies

Quality Risk Management (QRM)

Quality Risk Management (QRM) is a pivotal aspect of the PQS. It involves identifying, assessing, and mitigating risks throughout the manufacturing process. This proactive approach helps CDMOs minimize the potential for errors and enhance patient safety.

Core Components of a Pharmaceutical Quality System (PQS)

For a PQS to be effective, it must incorporate several essential components:

- Quality Policy and Objectives: Define clear quality goals aligned with industry standards and client expectations.

- Document Control: Maintain thorough documentation of all processes, changes, and training to facilitate transparency and compliance.

- Quality Processes: Establish standard operating procedures (SOPs) for all operations, from raw material sourcing to product release.

- Training Management: Implement a comprehensive training program to ensure all staff understand their roles in maintaining quality.

- Management System: Create a robust management structure that oversees and supports quality initiatives.

Implementing an Effective Pharmaceutical Quality System

Steps to Design and Implement a PQS

For CDMOs aiming to establish a successful pharmaceutical quality system, consider the following steps:

- Comprehensive Design: Develop a PQS that addresses all facets of quality management while adhering to Good Manufacturing Practice (GMP) standards.

- Full Documentation: Ensure that all procedures, protocols, and changes are meticulously documented and readily accessible.

- Correct Implementation: Train personnel thoroughly on their responsibilities within the PQS framework.

- Monitoring for Effectiveness: Regularly evaluate the PQS through internal audits and reviews to ensure it meets established objectives.

- Management Support: Secure commitment and resources from senior management to foster a culture of quality throughout the organization.

Continuous Improvement

An effective PQS should incorporate a continuous improvement framework. This includes:

- Regularly assessing process performance and product quality metrics.

- Utilizing feedback to refine procedures and address emerging challenges.

- Emphasizing quality improvement initiatives through innovative practices and technologies.

Challenges in Maintaining a Pharmaceutical Quality System

Common Pain Points

Despite the clear benefits, CDMOs may encounter challenges in maintaining an effective PQS, including:

- Complexity of regulatory requirements

- Resistance to change within the organization

- Insufficient resources for quality initiatives

- Gaps in training and support for personnel

Strategies to Overcome Challenges

To address these challenges, CDMOs can:

- Invest in quality management software to streamline processes and enhance compliance.

- Foster a quality-centric culture that prioritizes excellence at every level of the organization.

- Implement robust training management systems to keep staff informed about the latest quality practices.

Technology in Pharmaceutical Quality System

The Role of Electronic Quality Management Systems

Electronic Quality Management Systems (eQMS) are increasingly vital in the pharmaceutical industry. These digital solutions enable CDMOs to:

- Monitor quality metrics in real-time

- Streamline document control and training management

- Enhance collaboration across departments

Leveraging Technology for Quality Assurance

Pharmaceutical manufacturers can leverage technology to enhance their PQS by integrating:

- Automated workflows for quality processes

- Data analytics for risk assessment and informed decision-making

- Cloud-based solutions for document management and training

Measuring Success: Key Performance Indicators

Defining KPIs for Quality Management

To gauge the effectiveness of a pharmaceutical quality system, CDMOs should establish clear key performance indicators (KPIs), such as:

- Rate of product recalls

- Compliance audit scores

- Frequency of non-conformance reports

- Employee training completion rates

Regular Management Review

Conducting regular management reviews is essential to ensure that quality objectives are being met. These reviews should focus on:

- Analyzing data from the product quality monitoring system, which is designed to ensure that products are manufactured to the highest quality standards and that any deviations or issues are promptly identified and addressed.

- Identifying areas for improvement

- Reviewing Corrective Action and Preventive Action (CAPA), which enables companies to identify and address issues promptly, preventing them from recurring in the future.

A robust pharmaceutical quality system is crucial for CDMOs aiming to establish themselves as reliable partners for pharmaceutical companies. By implementing best practices, embracing technology, and fostering a culture of continuous improvement, CDMOs can enhance their PQS and navigate the complexities of the industry effectively. Ensuring high-quality standards not only supports regulatory compliance but also plays a vital role in safeguarding patient health and enhancing the overall reputation of the organization.

Frequently Asked Questions (FAQs) about Pharmaceutical Quality System

What are the pharmaceutical quality systems?

Pharmaceutical quality systems are structured frameworks that guide quality-related activities in the pharmaceutical industry, ensuring compliance with regulatory standards and maintaining product quality.

What is the pharmaceutical quality system in the UK?

In the UK, the pharmaceutical quality system must comply with the Medicines and Healthcare products Regulatory Agency (MHRA) standards, ensuring that all medicinal products meet safety and efficacy requirements.

What are the six pharmaceutical quality systems as defined by FDA?

The FDA defines six pharmaceutical quality systems, focusing on aspects such as quality assurance, quality control, process performance, documentation, training management, and risk management.

What is the QMS system in pharma?

The Quality Management System (QMS) in pharma is a set of policies, processes, and procedures that govern how a pharmaceutical organization ensures product quality and compliance with regulatory standards. It is an integral part of the pharmaceutical quality system.