Table of Contents

For pharmaceutical companies with promising non-sterile liquid formulations, the path from the laboratory bench to commercial production can be both exhilarating and daunting. Whether you are a startup seeking your first commercial launch or an established pharma company expanding your portfolio, your choice of CDMO (Contract Development and Manufacturing Organization) is crucial. After all, you are not just looking for a manufacturer—you need a trusted partner committed to quality, flexibility, and your vision.

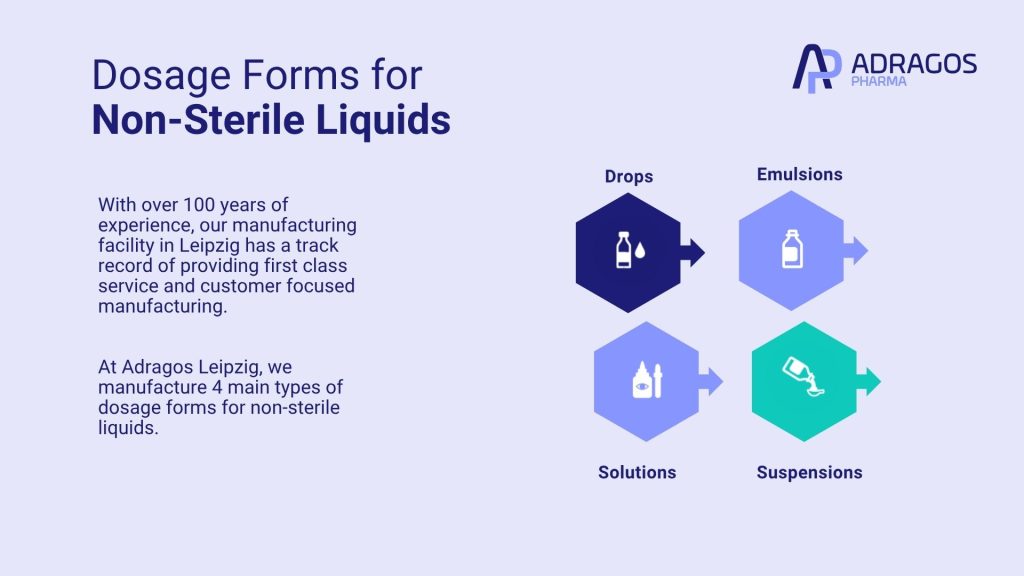

At Adragos Pharma Leipzig, we understand your unique challenges and ambitions. With a legacy of technical excellence, regulatory mastery, and a relentless focus on partnership, we deliver non-sterile liquids for the world’s most demanding markets, every single day.

What Are Non-sterile Liquids and Why Are They Important?

Non-sterile liquids encompass a diverse range of pharmaceutical dosage forms, solutions, drops, suspensions, and emulsions, that do not require sterile processing. These forms are administered orally or topically and are essential for many everyday therapies: think cough syrups, nasal drops, and oral suspensions for both adults and children. Oral suspensions are part of a broader group known as oral formulations, which include various types designed for ease of use across patient populations. Unlike injectables or certain ophthalmic products, these do not need to be entirely free from micro-organisms, but they must still meet strict safety and quality standards.

Moving a non-sterile liquid from development to production demands careful balance: the preparation of the formulation must maintain efficacy and stability, choose the right containers, ensure compliance, and ultimately safeguard patient trust. Non-sterile liquids offer advantages such as dosing accuracy, ease of use, and suitability for pediatric and geriatric populations, which help improve patient compliance and simplify administration.

Your Manufacturing Pathways: What Are the Options?

As you weigh your manufacturing choices, you will find three broad paths. Choosing the right manufacturing path can be beneficial for addressing formulation challenges and ensuring effective drug development.

1. Local Specialized CDMOs

Smaller, regional partners often offer personal service and expertise in niche batches, and can manufacture small-scale non-sterile liquid products tailored to client needs. Flexibility can be high, but you may outgrow their capacity as your product scales.

2. Large Multinational CDMOs

These bring robust infrastructure and deep regulatory experience, and typically provide integrated testing services to ensure product safety and compliance. However, you might find yourself lost in the crowd, and personalized support or custom solutions can be harder to secure.

3. In-house Manufacturing

While keeping everything internal offers maximum control, companies can produce non-sterile liquid products in-house, provided they invest in the necessary resources. However, the investment in equipment, validation, staff, and inspection readiness is daunting, particularly for novel or high-volume projects.

What Sets Adragos Leipzig Apart?

Adragos Leipzig combines the best of both worlds: the agility and expertise of a local partner, backed by the resources and rigor of a global CDMO. Our integrated supply chain management ensures seamless drug development, manufacturing, packaging, and distribution, supporting your project from start to finish. We make your success our mission, not just a transaction but a true collaboration.

Why Choose Adragos Leipzig? A Closer Look Inside

1. Comprehensive Dosage & Formulation Expertise

We handle a full spectrum of non-sterile liquid products. Whether you need solutions, drops, suspensions, or emulsions, our team can formulate and scale your project smoothly. The formulation process involves dissolving or suspending active pharmaceutical ingredients (APIs) and drug substances to ensure product stability and efficacy. With batch sizes up to 4,000 liters, you’ll never have to second-guess your CDMO’s capacity as your product grows from pilot to full market release.

Adragos Leipzig also has experience with semi solid dosage forms such as creams, gels, and lotions, as well as powders, to meet diverse client needs.

2. Flexible Packaging

Patients and healthcare providers rely on packaging that is safe, convenient, and suited to their needs. We fill both plastic and glass bottles, ranging from 20ml up to 700ml, offering both small-scale and bulk presentation for various markets. These products are carefully packaged to maintain stability and quality. Packaging components play an important role in preserving product integrity throughout the shelf life.

3. Leading Edge Technologies

Your product is in capable hands: our three specialized production lines, Dovema, Groninger, and Würschum, offer precision filling, efficient line speeds, and scalable output. Advanced automation means less risk of errors and consistent quality, batch after batch.

4. Relentless Commitment to Quality and Safety

At Adragos Leipzig, quality is never “good enough”: it is everything. We proudly operate under the most rigorous international standards:

- EU GMP-certified for both human and animal healthcare products.

- Strict adherence to German Arzneimittelgesetz (AMG) and serialization in line with EU FMD (to combat counterfeiting).

- Certification by the local Veterinär- und Lebensmittelaufsichtsamt assures safety and compliance for cosmetics and food supplements too.

- Regular monitoring and testing for bacteria to ensure product safety, efficacy, and regulatory compliance.

5. Thorough Quality Control and Analytical Capabilities

Every batch is subject to:

- Comprehensive routine analytics, from raw materials to finished product.

- Microbiological testing, ensuring bacterial counts stay within defined limits (TAMC & TYMC).

- Stability & dissolution testing, residual solvents analysis, and method validation (using HPLC, GC, UV-VIS, titration, and more).

- Full documentation for regulatory audits and transparent reporting for your team.

Non-sterile liquid manufacturing also supports individual dosing, which enhances versatility and patient compliance, especially for pediatric and geriatric populations.

6. Regulatory Know-How at Every Step

You do not have to be an expert in every regulation, we are. Our processes and permissions are validated by German and EU health authorities (including Landesdirektion Sachsen). We guide you through documentation, validation, and market submission, with a focus on prescription labeling and compliance to ensure accurate dispensing and proper product identification, so you can focus on your product and patients, not paperwork.

Microbial Contamination Prevention: Safeguarding Product Integrity

Preventing microbial contamination is a cornerstone of non-sterile liquid manufacturing. Even though non-sterile drugs are not required to be completely free of microorganisms, strict adherence to regulatory guidelines ensures that any microbial presence remains well within safe limits. At every stage of the manufacturing process, from the selection of raw materials to the final packaging, robust controls are in place to minimize the risk of contamination.

Key strategies include sourcing high-quality raw materials, maintaining a clean and controlled production environment, and implementing rigorous cleaning and sanitation protocols for all equipment. Regular microbiological testing of both the environment and the product itself helps detect and address any potential issues before they impact product quality. Additionally, staff training and strict process documentation ensure that every batch of non-sterile oral liquids, solutions, and suspensions meets the highest standards for safety and efficacy.

By prioritizing contamination prevention, pharmaceutical manufacturers protect both their products and the patients who rely on them, reinforcing trust in the quality of non-sterile preparations.

Facility and Equipment: Where Innovation Meets Precision

The quality of non-sterile liquid pharmaceuticals depends not only on the formulation but also on the environment in which they are produced. At Adragos Leipzig, our facility is designed to support the highest standards of pharmaceutical manufacturing. Every aspect of our production environment, from advanced air filtration systems to precise temperature and humidity controls, is engineered to minimize contamination risks and ensure consistent product quality.

Our advanced equipment, including specialized filling lines and automated packaging systems, allows us to handle a wide variety of dosage forms and batch sizes with precision and efficiency. This flexibility enables us to accommodate everything from small-scale development batches to large-scale commercial manufacturing, all while maintaining strict adherence to regulatory requirements. By investing in the latest technologies and maintaining rigorous maintenance schedules, we ensure that every non-sterile liquid, oral solution, and suspension is manufactured to exacting standards.

Innovation and precision are at the heart of our manufacturing services, providing pharmaceutical companies with the confidence that their products are produced in an environment where quality is never compromised.

What Is It Like to Work with Us?

Pharmaceutical manufacturing is dynamic and sometimes unpredictable. At Adragos Leipzig, we work as an extension of your team, answering questions quickly, offering proactive solutions, and always seeking ways to help you succeed. Whether you’re launching your first product or scaling up an established brand, you’ll experience transparency, reliability, and real partnership.

Choosing the right partner for non-sterile liquid manufacturing is a decision that shapes the future of your pharmaceutical product. At Adragos Leipzig, we combine deep expertise, cutting-edge technology, and a steadfast commitment to quality to deliver manufacturing services that exceed industry standards. Our comprehensive approach, from contamination prevention to advanced facility management, ensures that every oral liquid, solution, and suspension is produced with the utmost care.

Whether you are developing a new medication or scaling up for commercial manufacturing, our team stands ready to support your vision with flexibility, transparency, and unwavering dedication. Trust Adragos Leipzig to be your partner in non-sterile liquid excellence, where your product’s quality and your patients’ safety are always our top priorities.

FAQs about Non-sterile Liquids

What are examples of non-sterile?

Non-sterile pharmaceutical products include oral syrups, cough mixtures, nasal drops, topical solutions, and some ophthalmic and veterinary liquids that do not require complete sterility. Many over-the-counter medications are also formulated as non-sterile liquids for consumer use without a prescription.

What are sterile liquids?

Sterile liquids are formulated to be completely free from any living microorganisms. These include injectable medications, certain ophthalmic solutions for direct eye injection, infusions, and intravenous fluids.

What does non-sterile mean?

Non-sterile means the product is not processed to eliminate all microbial life, though it must still be within tightly controlled microbiological limits. These products remain safe and effective for their intended use.

Which can be a non-sterile product?

Products such as oral suspensions, cough syrups, some eye or nasal drops (not injected), dermatological solutions, and certain animal health formulations are all examples of non-sterile products.

What is the difference between sterile and non-sterile?

Sterile products undergo processes designed to destroy all forms of microbial life and are used when there is risk of infection (such as injections). Non-sterile products do not require this level of control but must be manufactured under hygiene-controlled conditions with defined microbial limits.

What are examples of sterile products?

Examples of sterile pharmaceutical products include vaccines, injectable medications, infusion solutions, intraocular eye treatments, and sterile ointments for wounds.