Jura, Switzerland

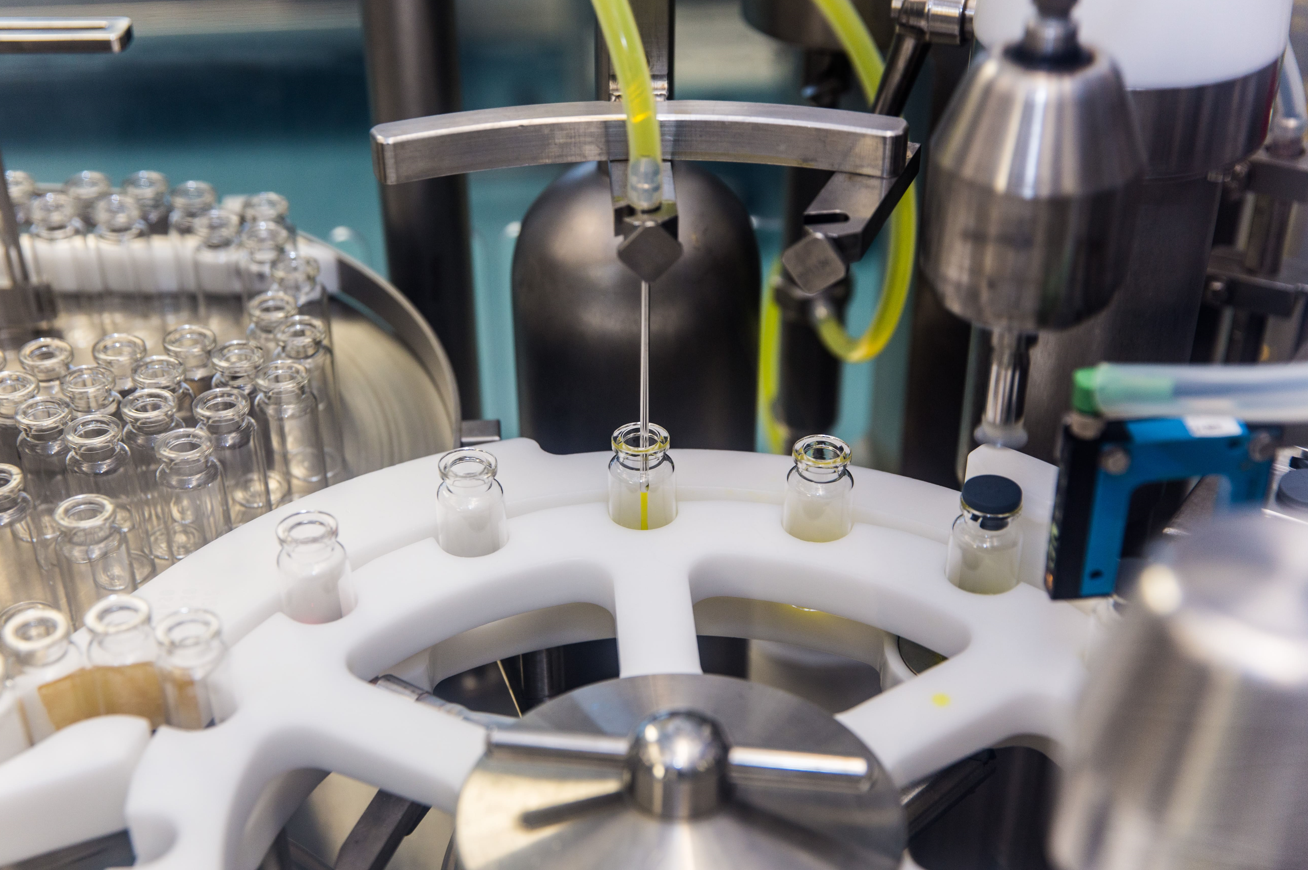

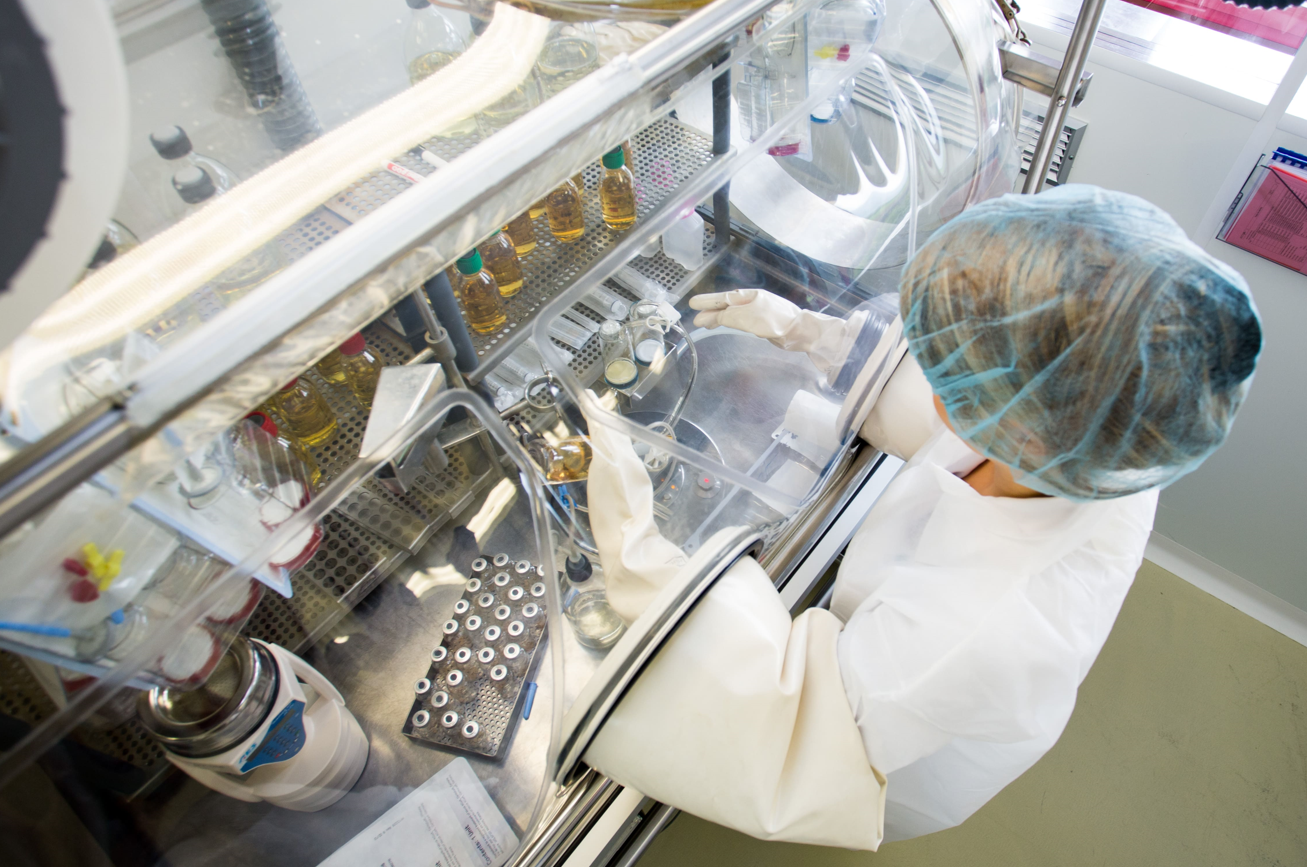

With over 20 years of experience, our Swiss facility offers a complete range of services tailored to both clinical and commercial manufacturing needs. We specialise in the aseptic production of lyophilised or liquid sterile (bio)pharmaceutical products through fill and finish. Our facility is ideal for the production of small clinical and commercial batches and is GMP and FDA certified, demonstrating our commitment to the highest standards of quality and safety.

Our Site

Our offerings include scale-up, technology transfer, GMP and FDA processes, and stability studies to ensure top-tier quality and compliance at every stage. By integrating technology, technical expertise, and regulatory support, we empower clients to streamline their processes from development to GMP storage, ensuring efficiency and precision.

Strong Project Management

Our robust project management system ensures proactive communication and seamless coordination, keeping every project on track from start to finish.

Flexible Batch Production

We adapt to each project’s unique needs, offering tailored solutions and adjusting timelines to ensure client satisfaction, no matter the complexity.

Additionally, we don’t impose minimum batch size, giving you the flexibility to produce exactly what you need, tailored to your specific project requirements.

Aseptic Process Simulation (APS)

We offer fully compliant APS services to ensure sterility and maintain product safety and efficacy in your manufacturing processes.

GMP and FDA Regulatory Support

We provide comprehensive GMP and FDA regulatory guidance and technical support, helping you navigate complex clinical projects with ease and ensuring compliance with top industry standards.

API Management Expertise

We specialize in handling limited quantities of valuable APIs, maximizing efficiency and ensuring top-quality results for your batches.

Our Offering

Adragos Jura offers Swiss-quality pharmaceutical solutions, combining unmatched flexibility and transparency to support your development with precision and trust.

Scale-Up

Technology Transfer

Preclinical Supply

GMP Process

GMP Clinical Batches

Release Analytics

Clinical Packaging

Stability Studies

GMP Storage

Clinical Distribution

Tech Transfer

Process Validation

GMP Commercial Batches

Release Analytics

Secondary Packaging

Serialization

On-Going Stability Studies

GMP Storage

Commercial Distribution

Our Services

We specialize in aseptic manufacturing of lyophilized or liquid sterile (bio)pharmaceutical drug products through fill and finish. We have a highly experienced team of 120 people working in more than 20 different professions.

Clinical Manufacturing – Phase I, II, & III

- Process Alignment with GMP

- Pilot Batch

- Scale Up

- GMP Manufacturing

- Secondary Packaging

- Randomized Labeling

- Clinical Kit Preparation

- GMP Storage

- Controlled Temperature Shipment

Commercial Manufacturing – Fill and Finish

We are specialized in two distinct dosage forms: liquid products aseptically filled and lyophilized products, both filled in vials.

Capacities:

- Aseptic Filling

- Liquid Filling

- Complex Formulation

- Peptides

- Biological Products

- Controlled Substances

- Small Molecules

- Sterile Suspensions

- Ophthalmic Products

- Placebos/Diluents

- Vials

- Lyophilizer Size (3.5 m²)

No minimum batch size is imposed. Specialized in the manufacturing of clinical batches from very small quantities of bulk solution (eg: 200-300ml).

We manufacture batches for the different phases of pharmaceutical development, from manufacturing under GMP and FDA conditions (first stage of scale-up under industrial conditions, preparation of material for preclinical studies, stability studies, etc.) to GMP/FDA manufacturing for clinical needs.

Development Services

- Freeze-Drying Cycle Development

- Manufacturing Process Development and Transfer

- Formulation Development Support

- Filter/Material Compatibility

- Client Specific Development Upon Request

Analytical Services

- HPLC-UV (assay, purity)

- UPLC-UV

- Sub-visible particle counting

- Osmolality

- Residual humidity by Karl Fischer (volumetric / coulometric)

- Spectrophotometry UV-Vis

- Spectrophotometry IR

- pH

- Visible particles

- SDS – Page

- Thin layer chromatography

- Potentiometry

- Viscosity

- TOC

- Sterility testing under isolator

- Endotoxins by kinetic turbidimetry

- Bioburden testing

- Specific germs contamination

Primary & Secondary Packaging

Primary Packaging

- The customer defined the packaging (stoppers and caps)

- Depends on the specificities of the product

Secondary Packaging

- Visual Inspection

- Labelling (manually or automatically)

Quality Control

QC activities are carried out in support of manufacturing activities at all stages of manufacturing :

- Analysis of raw materials and packaging items upon receipt and then released for use.

- In Process Controls (IPC).

- Sampling of the finished product to carry out the release testing.

Release Testing

In accordance with GMP, verification of the applicability of analytical and microbiological methods are performed to guarantee reliable and reproducible results.

a) Microbiological methods:

- Bioburden Test

- Sterility Test

b) Physico-chemical methods:

- HPLC/UPLC

- Endotoxin Test

Stability Studies

- Long-Term Stability Storage Under ICH Conditions

- Analytical Testing at Different Stability Points

GMP Batch Certification

- GMP certification of the company by Swissmedic (Swiss Health Authorities) for the production of lyophilized and liquid sterile products.

- GMP manufacturing of the first batches.

Download Our Brochure Now!

We have prepared a brochure to help you discover our facility in Jura.

Key Information

Location: Courroux, Jura, Switzerland

SQM: 6200 m²

Foundation Year: 1999

FTE (Employees): more than 110 people working in more than 20 different professions

Certifications

EU – GMP (Swissmedic)

US – FDA

Expertise

More than 20 years of experience

Apprentices trained in 4 different areas

Meet our experts

Highly skilled and well-trained scientist specialized in clinical and commercial manufacturing.

Meet our Colleague

Mike Stradling

Mike Stradling is the new Managing Director of our site in Jura, Switzerland. With extensive experience in sterile production and operational leadership, he is committed to driving our Swiss facility toward continued success and excellence. His many years of expertise ensure a promising future for our operations in Jura.

For a more comprehensive look into Mike’s professional profile, connect with him on LinkedIn.

Adragos Hub

Find out more about our Jura facility in our recent blog posts