Our Offering

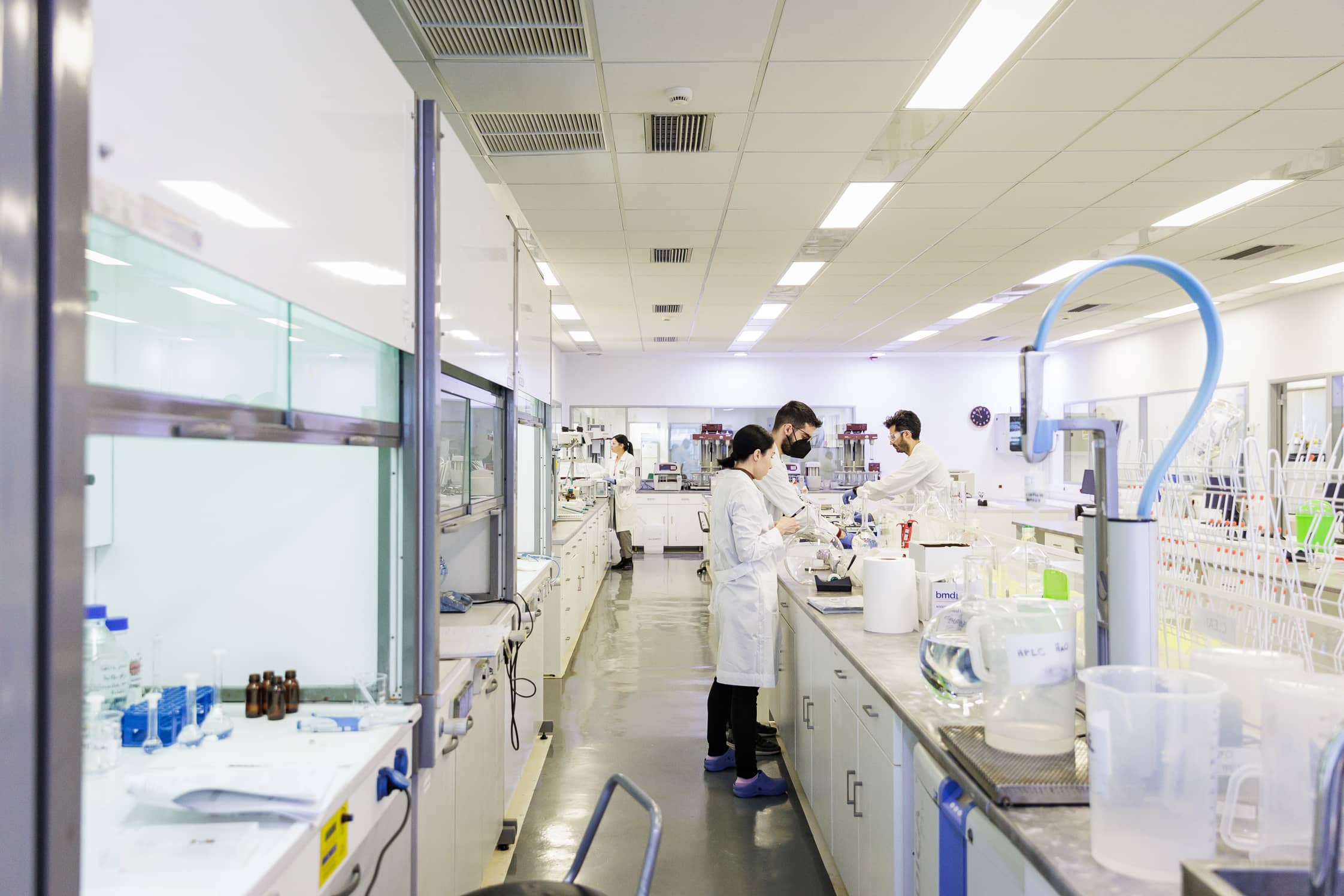

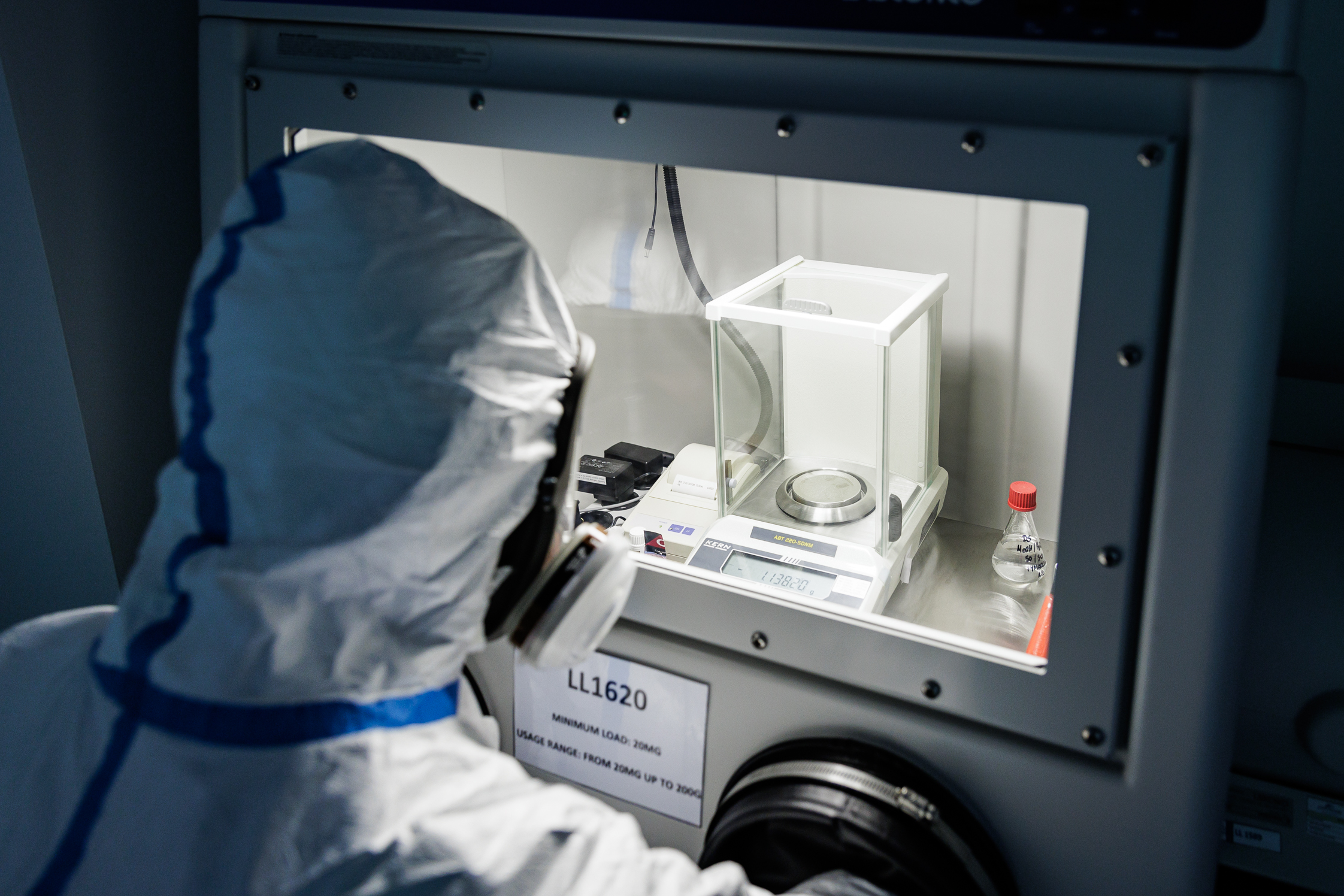

We are a reliable CDMO partner, offering comprehensive development and manufacturing services for drug products, ranging from small molecules to large molecules. Our expertise includes end-to-end production of small molecule finished dosage forms (FDFs), such as sterile and non-sterile liquids, solids, and semi-solids. Additionally, we specialize in biologicals, orphan drugs, clinical trials, fill-and-finish, and lyophilization.

Explore Our Key Services

We focus on development, formulation, commercial production, and packaging across various dosage forms, including sterile and non-sterile liquids, solids, and semi-solids products.

We provide customised CDMO services designed to meet the diverse needs of the industry. From out-licensing and supply to one-off analysis, custom developments, and advanced formulation services.

⟶Our CDMO manufacturing network includes three state-of-the-art facilities in Europe and one in Japan, each staffed with a dedicated team committed to delivering unparalleled quality in every offering and solution we provide.

⟶We guide your project through every phase of clinical manufacturing, from feasibility studies and preclinical material preparation to GMP-compliant production. Our end-to-end approach ensures seamless transitions between phases, delivering high-quality solutions tailored to your clinical needs.

⟶We offer fully integrated CDMO services covering the entire process: from initial planning and supply chain management to regulatory affairs, for your drug product.

⟶Download Our Brochure Now!

We have prepared a brochure to help you discover our comprehensive global CDMO portfolio.

Frequently Asked Questions (FAQs)

What makes Adragos Pharma a reliable CDMO partner?

Our commitment to quality and customer-centric approach sets us apart. With a global presence across five strategic locations, we provide seamless coordination and communication, helping clients save valuable time. Our expertise and end-to-end service offerings allow our clients to focus on their core business while we manage their drug development and manufacturing needs.

What are the benefits of partnering with a CDMO for drug development and manufacturing?

Partnering with a CDMO streamlines the drug development process, providing access to specialized facilities, regulatory expertise, and end-to-end support. This partnership allows you to focus on your core competencies, reduce time-to-market, and optimize resources while ensuring that high-quality products are developed and manufactured efficiently.

How does Adragos Pharma ensure compliance with global regulatory standards?

Adragos Pharma strictly adheres to the latest standards set by regulatory authorities like the FDA (U.S. Food and Drug Administration), EMA (European Medicines Agency), and PMDA (Pharmaceuticals and Medical Devices Agency in Japan). We implement rigorous quality control and assurance measures at every stage of development and manufacturing to meet the highest standards of safety and efficacy, ensuring our clients’ products are fully compliant for global markets.

Can Adragos Pharma accommodate tight timelines for drug development and manufacturing?

Yes, our customer-centric approach allows us to be highly flexible with project timelines. By utilizing our global network of facilities and expertise, we can accelerate development and manufacturing processes without compromising on quality. Our dedicated project managers work closely with clients to ensure that deadlines are met, helping you bring your product to market as quickly as possible.

How does Adragos Pharma support clients with complex or niche formulations?

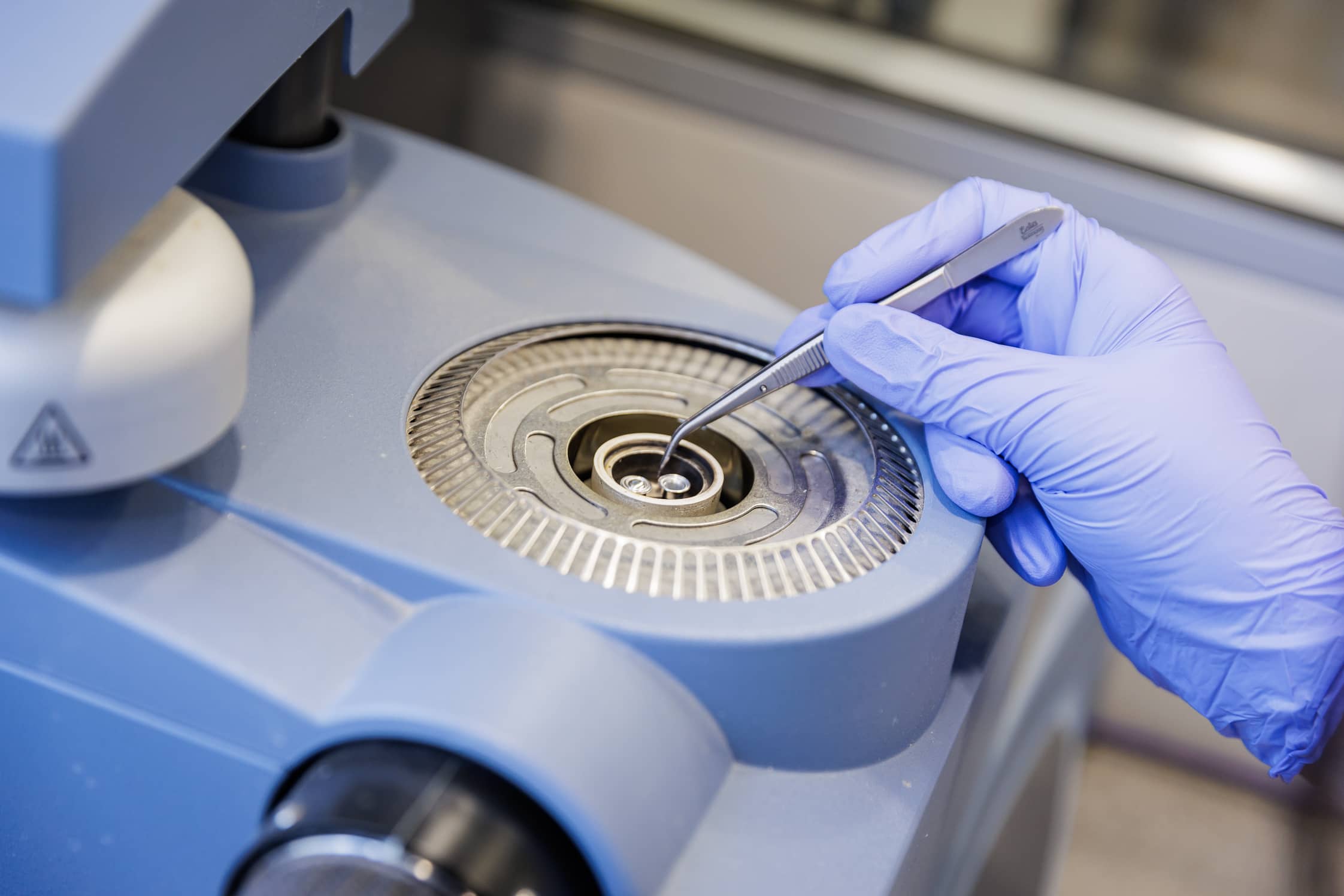

We specialize in small molecule finished dosage forms and have extensive experience with complex formulations, including sterile, semi-solids, and non-sterile liquids. Our team of scientists and engineers collaborate closely with clients to develop tailored solutions that address unique challenges. By leveraging our Athens development center and global manufacturing sites, we ensure that even the most specialized products are developed and manufactured to the highest standards.

How can a CDMO help optimize my drug product’s manufacturing process?

CDMOs offer extensive process development expertise, using advanced technologies and analytical methods to optimize manufacturing processes. By refining formulations, enhancing batch scalability, and implementing cost-efficient strategies, they help reduce production costs and improve product quality, ultimately ensuring a smoother path to market and a more competitive product.