- Home

- Visual Inspection

Visual Inspection

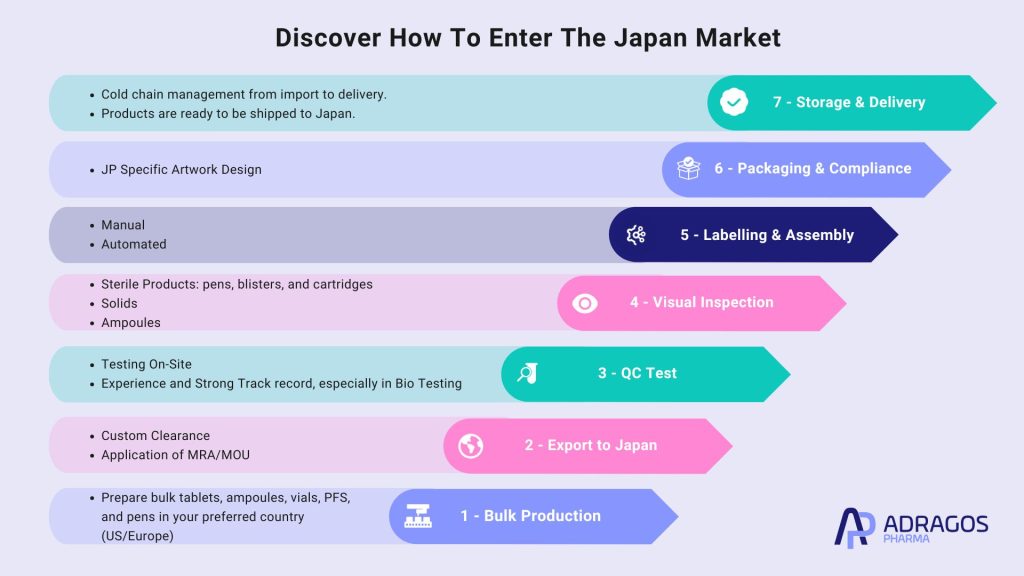

Navigating Japan’s pharmaceutical landscape can be challenging for non-Japanese companies, given its stringent quality standards. We offer a solution to this challenge by handling visual inspection (VI) and packaging locally in Japan, we enable you to focus on producing bulk vials or Pre-Filled Syringes in the US/EU, and then export them to Japan with ease.

Import Sterile: Vials & Prefilled Syringes

From pens and blisters to cartridges and vials, our visual inspection services cover a broad spectrum of sterile products, ensuring compliance and safety.

- Cold Storage Capacity: 1,650 pallets

- Inspection Capacity: 104 inspectors (manual inspection)

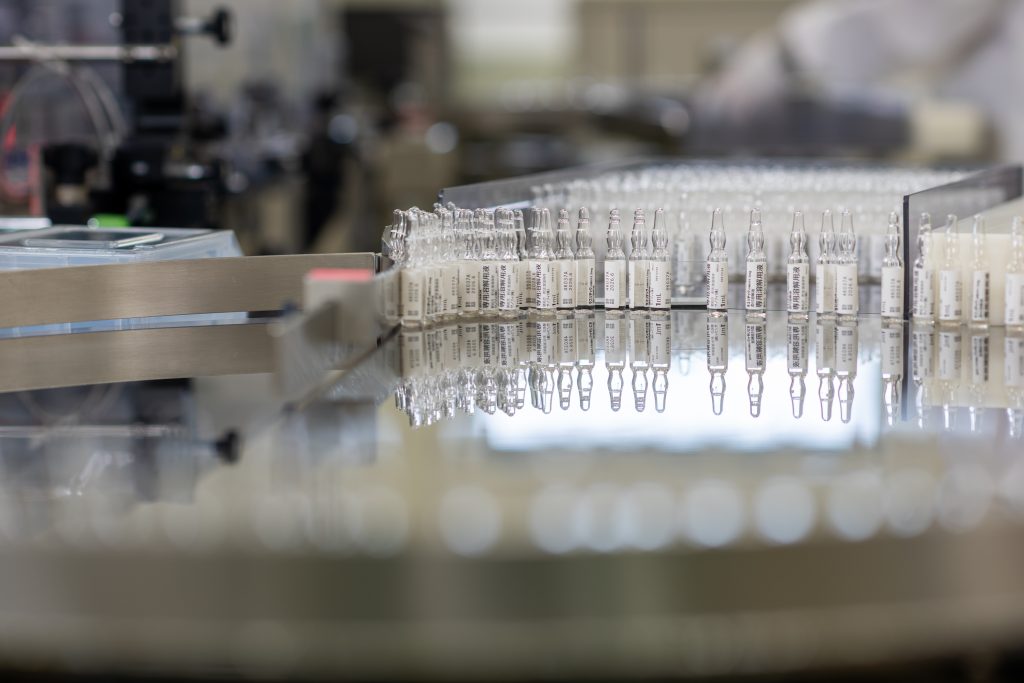

Sterile Liquids: Ampoules

Specializing in the inspection of 30 millions ampoules per year, we ensure each one meets the strictest quality standards.

- Encompassing formulation

- Filling with terminal sterilization

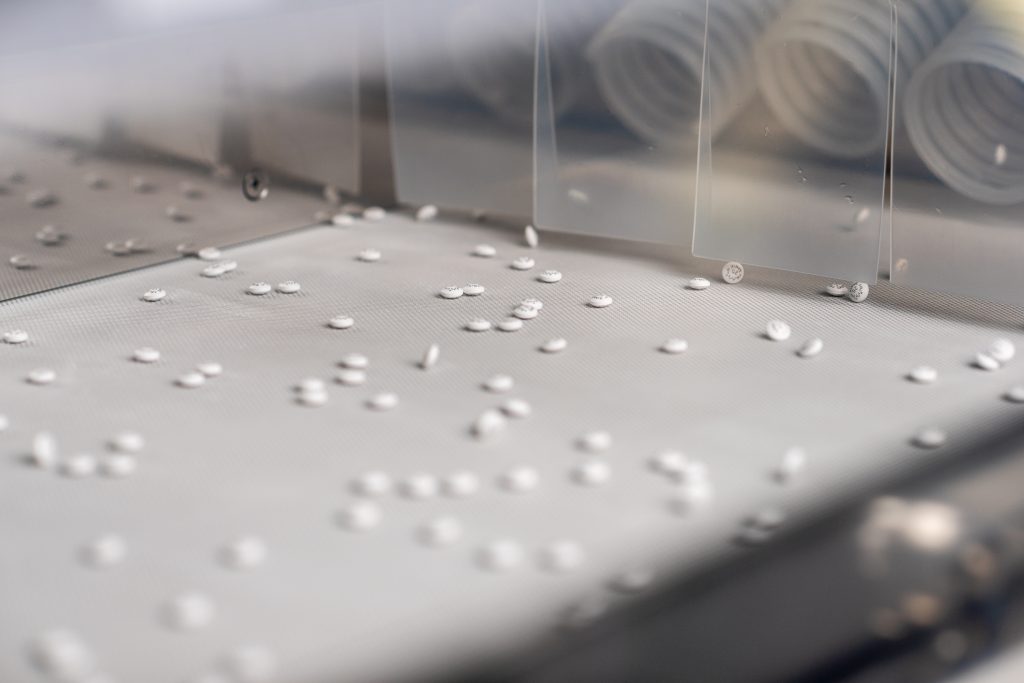

Oral Solids: Tablets

With the capacity to inspect up to 2 billions tablets per year, our services are equipped to handle your highest volumes without compromising on accuracy.

Inspection Machine for Solids

For solids such as uncoated and film-coated tablets, our state-of-the-art inspection machine can process up to a maximum of 10,000 tablets per minute, combining speed with precision to support your production demands.

Download Our Brochure Now!

We have prepared a brochure to help you discover all our visual inspection services that our facility in Kawagoe has to offer.

How We Can Help You To Enter The Japan Market

- Adherence to Regulations: Our visual inspection services are specifically structured to help our clients comply with stringent pharmaceutical regulations, ensuring your products are market-ready.

- Advanced Technology: Utilizing the latest in visual inspection technology, we offer services that are not only efficient but highly accurate, reducing the risk of quality issues.

- High Capacity: Our impressive capacity allows us to handle large volumes, making us the perfect partner for pharmaceutical companies with significant production needs.

- Tailored Solutions: Understanding that each client has unique needs, we offer customized visual inspection services designed to meet the specific requirements of your products.

Our services designed for your unique requirements!

Our visual inspection services meet pharmaceutical standards with unmatched precision and reliability, using cutting-edge technology to ensure Japanese market compliance. We can provide you with the specific solutions to meet the specific needs of injectables and imported sterile products.

We offer oral visual inspection services in Kawagoe, Japan

Adragos Kawagoe is our cutting-edge manufacturing facility located at the north of Tokyo with a strategic location that aligns with the heartbeat of pharmaceutical innovation in Japan.

Adragos Hub

Find out more about Visual Inspection in our recent blog posts

![MAH Transfers in Japan & Smooth Market Entry [Case Study]](https://adragos-pharma.com/wp-content/uploads/2024/05/Adragos-Pharma-26-1024x480.jpg)

![How a European Biopharma Entered Japan [Case Study]](https://adragos-pharma.com/wp-content/uploads/2024/04/Adragos-Pharma-39-1024x480.jpg)

![How To Enter The Japanese Market [Webinar]](https://adragos-pharma.com/wp-content/uploads/2025/03/Visuals-for-the-Kawagoe-webinar-1-for-web.jpg)