In the pharmaceutical industry, adherence to stringent regulatory standards is paramount. For companies seeking a reliable Contract Development and Manufacturing Organization (CDMO), understanding how potential partners comply with regulations like the European Union’s Good Manufacturing Practice (EU-GMP) and the oversight provided by the regulator is crucial. Regulators play a critical role in overseeing compliance, ensuring that companies meet the required standards through various mechanisms for monitoring and enforcement.

Halden Pharma is , among others, EMA and FDA certified, underscoring its commitment to maintaining the highest quality standards in sterile production, and ships to all major global markets.

Understanding EU-GMP Regulatory Standards

What is EU-GMP?

EU-GMP refers to the European Union’s guidelines for Good Manufacturing Practice, which ensure that medicinal products are consistently produced and controlled according to quality standards appropriate for their intended use. Compliance with EU-GMP is mandatory for pharmaceutical manufacturers operating within the EU and for those exporting products to the EU market.

Halden Pharma’s Commitment to Regulatory Compliance

Comprehensive Certifications

Halden Pharma holds multiple regulatory certifications, including EU-GMP, US-FDA, Brazil-ANVISA, Japan-PMDA, China-NMPA, and Turkey-MOH. These certifications underscore the facility’s commitment to maintaining the highest international standards in pharmaceutical manufacturing.

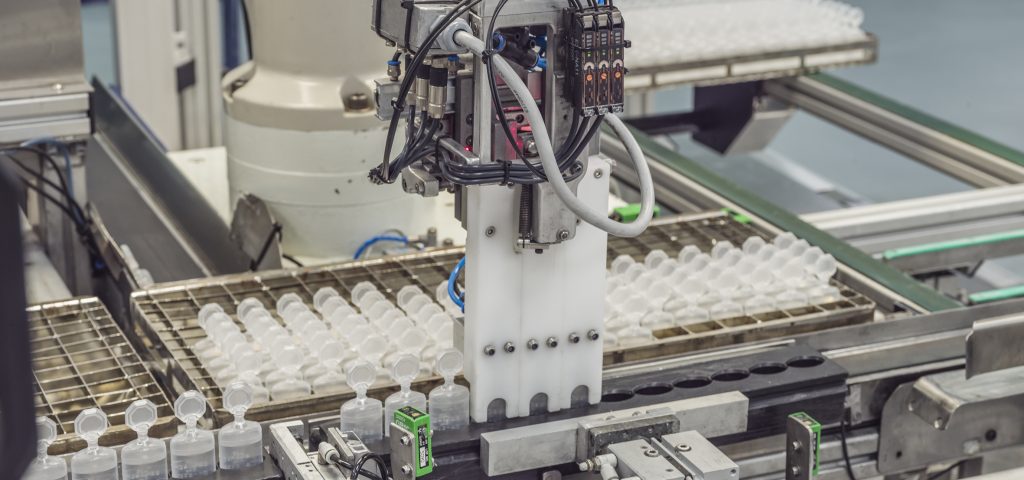

Advanced Manufacturing Capabilities

Located in Halden, Norway, the facility spans 77,000m² and employs 650 professionals. Its capabilities include the production of sterile liquids, non-sterile liquids, gels, and the use of blow-fill-seal technology. With seven production lines and a 95% export rate, Halden Pharma demonstrates its capacity to meet global pharmaceutical demands.

Quality Control and Risk Management

Halden Pharma emphasizes quality control and quality risk management to ensure product safety and efficacy. By adhering to EU-GMP guidelines, the facility implements robust processes to identify and mitigate risks throughout the manufacturing process.

Supplier Qualification

The facility follows stringent procedures for supplier qualification, ensuring that all materials and services meet EU-GMP standards. This includes conducting regular audits and assessments of suppliers to maintain the integrity of the supply chain.

Infrastructure and Resources

Compliance with GMP and GDP requires significant infrastructure and resources. Halden Pharma is equipped with state-of-the-art facilities, advanced equipment, and a team of highly qualified personnel to ensure that our products are manufactured and distributed following regulatory standards.

Equipment and Facilities

The equipment and facilities used in the production and distribution of medicinal products at Halden Pharma are designed to meet the highest regulatory standards. We ensure that all equipment and facilities are suitable for their intended use, properly maintained, and regularly calibrated. The integration of computerized systems and advanced equipment helps us produce and distribute products in strict accordance with regulatory standards.

Regular inspections and audits are conducted to ensure ongoing compliance with regulatory requirements. This proactive approach ensures that our equipment and facilities remain at the forefront of industry standards, supporting our commitment to quality and safety.

Good Distribution Practice

Good Distribution Practice (GDP) is a critical component of the supply chain for medicinal products. At Halden Pharma, we adhere to GDP principles to ensure that the quality of our products is maintained from the manufacturer to the end-user. The European Medicines Agency (EMA) guides GDP, emphasizing the importance of compliance with GDP requirements for medicinal products.

Our distribution practices are designed to meet the regulatory standards and guidelines set by the European Union, including the EU GDP guidelines. We employ a risk-based approach to identify and mitigate potential risks to the quality of medicinal products during distribution.

Advantages of Partnering with Halden Pharma

Global Reach and Compliance

With certifications from multiple international regulatory bodies, Halden Pharma is well-equipped to serve pharmaceutical companies targeting global markets. Its compliance with various regulatory standards ensures that products manufactured at the facility can be distributed in numerous countries without additional regulatory hurdles.

Frequently Asked Questions about EU-GMP Regulatory Standards (FAQs)

What are EU-GMP standards?

EU GMP standards are guidelines established by the European Union to ensure that medicinal products are consistently produced and controlled according to quality standards appropriate for their intended

What are the regulatory requirements for EU-GMP?

Regulatory requirements for GMP include establishing a quality management system, ensuring qualified personnel, maintaining suitable premises and equipment, proper documentation, and conducting regular self-inspections.

Why are EU-GMP Regulatory Standards important when selecting a CDMO partner?

EU-GMP certification ensures that our facilities and processes meet the highest international standards for pharmaceutical manufacturing.

For clients, it means your products are built on a regulatory foundation trusted across Europe and globally — essential for market authorization, risk management, and speed to market.

How do EU-GMP Regulatory Standards contribute to commercial success?

EU-GMP Regulatory Standards isn’t just a regulatory box to check — it’s a commercial asset. It allows your product to be immediately eligible for sale across all EU member states and increases attractiveness for licensing deals, distribution agreements, and partnerships. Pharmaceutical companies, healthcare providers, and investors increasingly demand GMP-compliant production before entering into agreements. In short, EU-GMP accelerates market access, protects brand reputation, and opens new revenue channels.