Sterile injectables play a crucial role in patient care and the global healthcare system. These injectable drugs are essential for treating life-threatening diseases and managing chronic conditions. Given the nature of their application, sterile injectables must meet strict standards to ensure they are completely sterile and safe for administration.

What Are Sterile Injectables?

Sterile injectables refer to drugs that are administered via injection and are required to be free from any microorganisms. Unlike oral medications, which pass through the digestive system, these injectable drugs are administered directly into the body, typically through intravenous, intramuscular, subcutaneous, or intraarticular injections. This direct administration bypasses the body’s natural filters, making the sterility of these drugs an essential part of ensuring patient safety.

The Importance of Sterility in Injectables

Sterility is critical because any contamination in sterile injectables can lead to severe health risks, including infections, sepsis, or even death. To reduce the risk of such adverse effects, the manufacturing and sterile packaging processes are highly regulated and must adhere to stringent regulatory requirements set by authorities like the FDA.

Sterile Injectable Manufacturing Process

The sterile injectable manufacturing process involves several complex processes designed to prevent contamination and ensure the quality of the final product. This process includes:

- Aseptic Manufacturing: A method used to produce sterile injectables by ensuring that the sterile raw materials, equipment, and environment are free from microorganisms during the manufacturing process. It is crucial to maintain full sterility throughout the entire production process to produce sterile injectables.

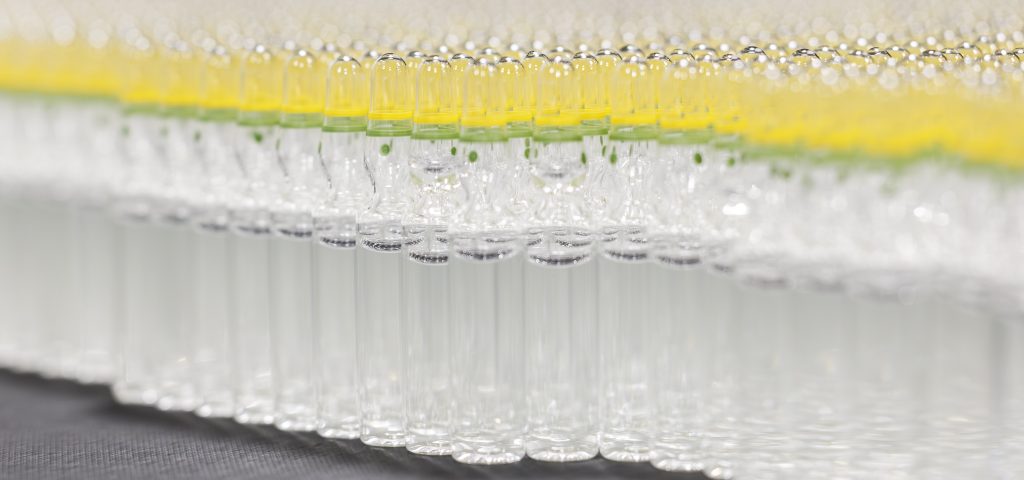

- Terminal Sterilization: This process involves sterilizing the final product in its sterile containers, such as vials or pre-filled syringes, to ensure that the sterile injectable remains free from contamination until it reaches the patient.

- Fill-Finish: This is the final step in the manufacturing process, where the sterile injectable drugs are filled into sterile containers and sealed under carefully controlled conditions to maintain sterility.

Challenges in Manufacturing Sterile Injectables

Manufacturing sterile injectables presents several significant challenges that require specialized expertise and stringent controls. These challenges include:

- Maintaining a Sterile Environment:

Ensuring a completely sterile environment throughout the manufacturing process is one of the most critical challenges. Any introduction of microorganisms can compromise the sterility of the injectables, leading to potential contamination. This requires meticulous control of the air quality, surfaces, and personnel within the production facility. - Advanced Equipment Requirements:

The equipment used in producing sterile injectables must be designed to minimize the risk of contamination. This includes specialized machinery for aseptic manufacturing and sterile filling that is regularly sterilized and maintained to meet strict standards. The high costs and complexity of this technology make it a significant challenge for manufacturers. - Compliance with Regulatory Standards:

Adhering to stringent regulatory requirements imposed by authorities like the FDA is non-negotiable. The regulations cover every aspect of the manufacturing process, from sterile raw materials handling to the final step of sterile packaging. Compliance requires ongoing monitoring, documentation, and quality assurance to ensure that the injectable drugs meet all safety and efficacy standards. - Preventing Contamination:

Preventing contamination during the manufacturing and sterile packaging processes is a constant challenge. Even the smallest lapse in sterility can lead to contamination, rendering an entire batch unusable. This requires a combination of carefully controlled environments, rigorous testing, and continuous quality checks to ensure that the sterile end product is free from contaminants. - Complex Processes and Formulations:

The formulation of sterile injectable drugs often involves complex processes that must be executed with precision. The sensitive nature of these formulations means that certain sterile injectables cannot undergo terminal sterilization and must be produced through aseptic manufacturing methods, adding another layer of complexity to the production process. - High Costs and Investment:

The production of sterile injectables requires significant investment in state-of-the-art facilities, advanced technology, and highly trained personnel. These costs can be prohibitive, especially for smaller manufacturers, making it a significant challenge to scale operations while maintaining the necessary levels of quality and sterility. - Ensuring Consistent Quality:

Maintaining consistent quality across all sterile injectable products is vital. This requires robust quality control measures, including thorough testing at various stages of the manufacturing process to ensure that every unit meets the required sterility and safety standards. Any variation

Regulatory Requirements for Sterile Injectables

The FDA and other regulatory bodies impose strict regulatory requirements on the manufacturers of sterile injectables. These regulations ensure that the manufacturing processes adhere to the highest standards of quality and safety. Compliance with these regulations is non-negotiable, as it directly impacts patient safety and the efficacy of the drugs.

The Future of Sterile Injectables

As the global healthcare system evolves, the demand for sterile injectables is expected to grow. Innovations in technology and development will likely lead to more efficient manufacturing processes and improved quality of sterile injectable products. Additionally, the focus on patient care and safety will continue to drive advancements in the manufacturing and development of these critical drugs.

Understanding the sterile injectable manufacturing process and the importance of maintaining sterility throughout production is crucial for the pharmaceutical industry. These sterile injectables play a vital role in treating life-threatening diseases and managing chronic conditions. As such, ensuring their quality and safety is paramount to maintaining the integrity of the global healthcare system.

FAQs about Sterile Injectables

What is a generic sterile injectable drug?

A generic sterile injectable drug is a medication administered via injection that is bioequivalent to a brand-name product, with the same efficacy, safety, and sterility.

What are sterile drugs?

Sterile drugs are medications that are free from all microorganisms, ensuring they can be safely administered without the risk of infection or contamination.

How are injectables sterilized?

Injectables can be sterilized using methods like terminal sterilization, where the drug is sterilized in its final container, or through aseptic manufacturing, where sterility is maintained throughout the entire manufacturing process.

What is sterile used for injection?

Sterile refers to the complete absence of viable microorganisms. In the context of injections, it ensures that the drug can be safely administered directly into the body without causing harm due to contamination.