- Home

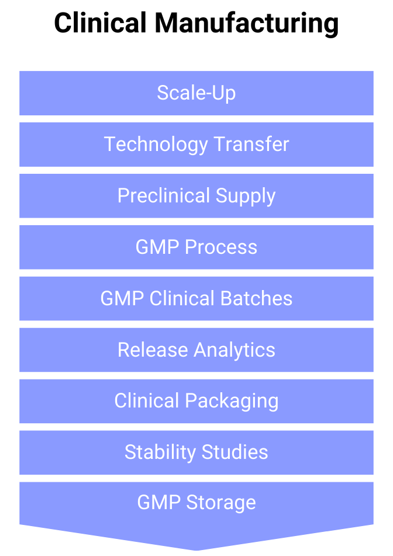

- Clinical Manufacturing

Clinical Manufacturing

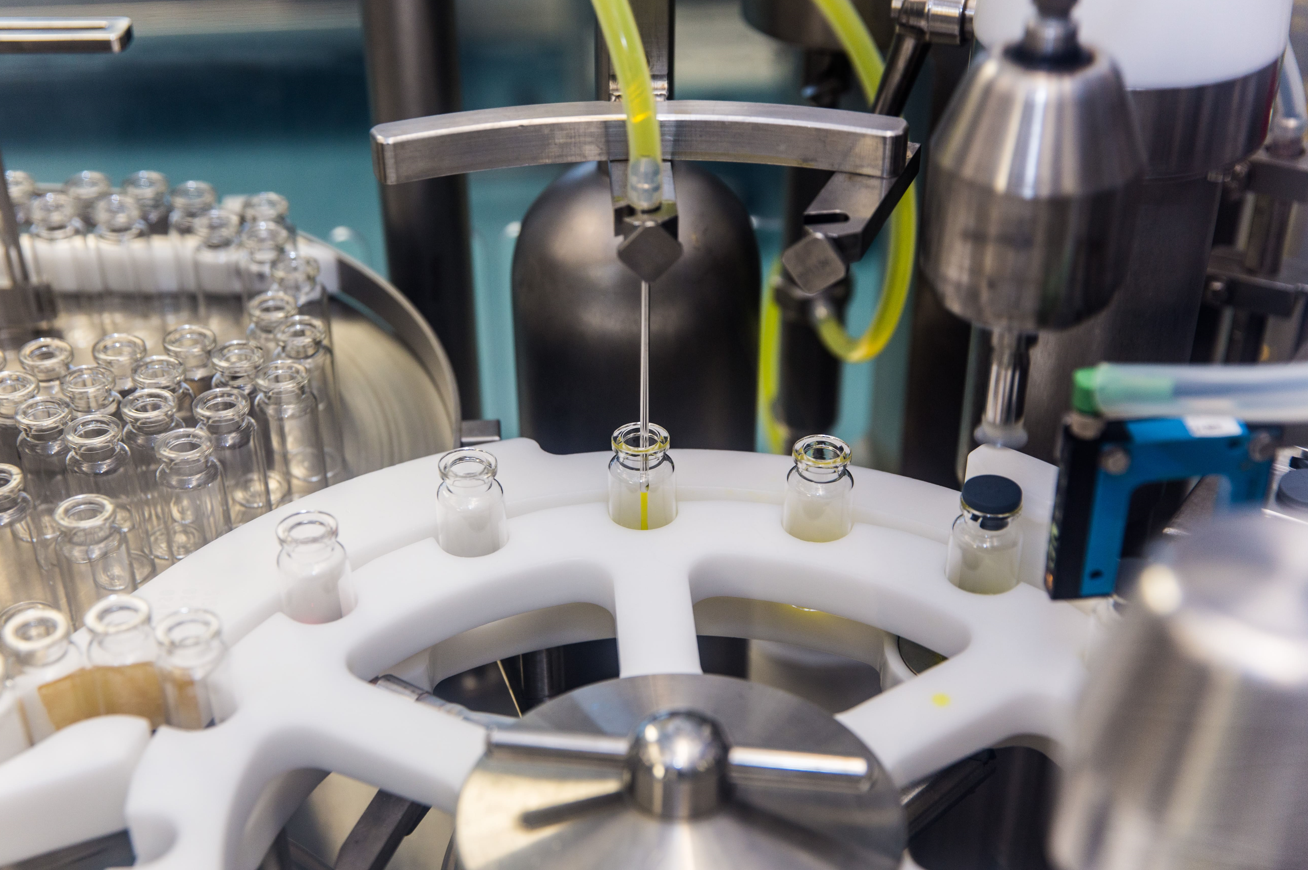

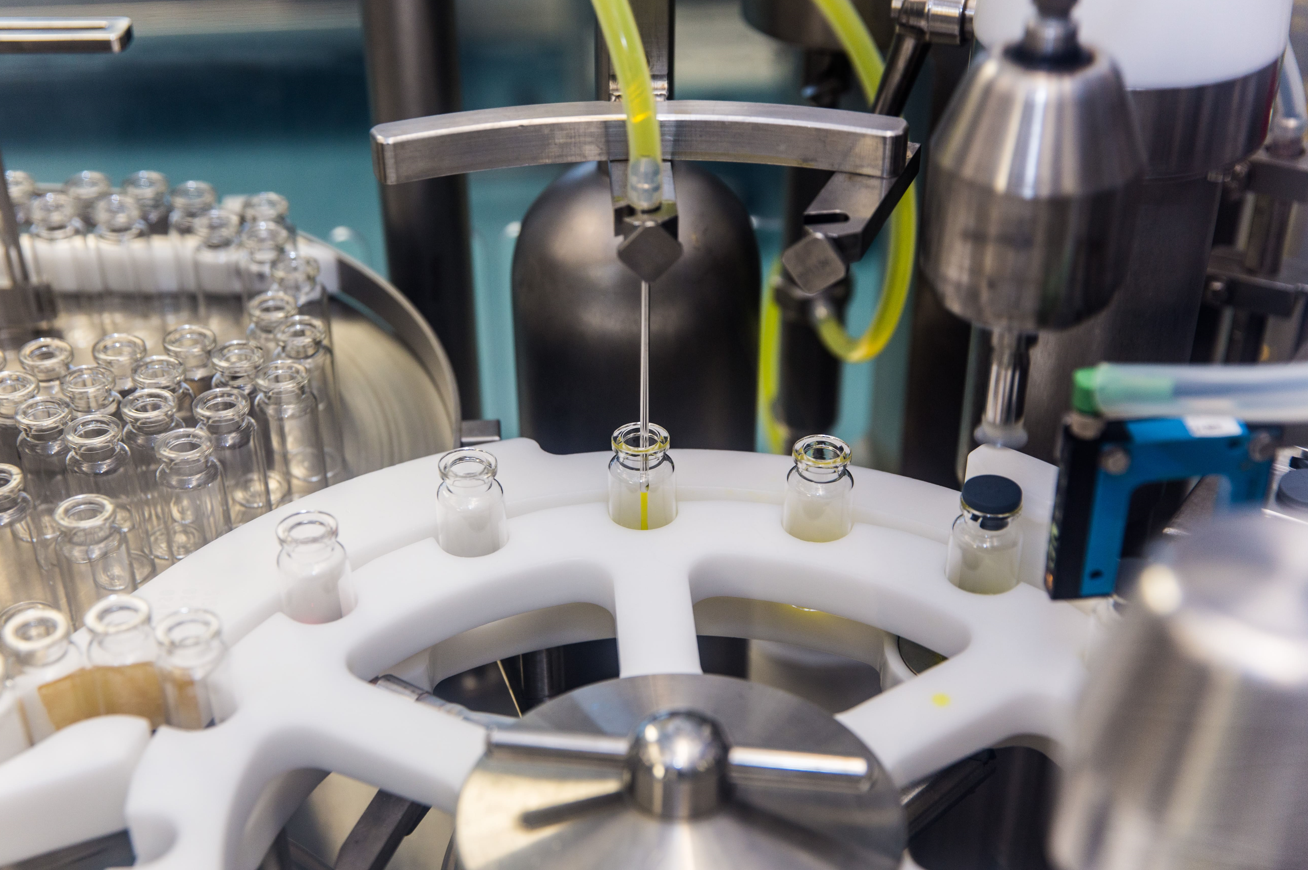

We guide your project through every phase of clinical manufacturing, from feasibility studies and preclinical material preparation to GMP-compliant production. Our end-to-end approach ensures seamless transitions between phases, delivering high-quality solutions tailored to your clinical needs.

Our Jura facility is dedicated to the aseptic production of lyophilized and liquid sterile (bio)pharmaceutical products using our Fill & Finish capabilities. Designed to produce clinical and small-scale commercial batches, our facility is both GMP and FDA certified, ensuring high standards of quality and compliance.

Process Alignement with GMP

Scale Up

GMP Manufacturing

Secondary Packaging

Clinical Kit Preparation

GMP Storage

Project Management

We are committed to providing personalized and continuous support throughout your project’s lifecycle.

Our approach includes:

- Initial Project Assessment: Collaborating closely with you to understand your project’s unique requirements.

- Dedicated Project Managers: Serving as proactive liaisons between you and our internal team, ensuring seamless communication.

- Dynamic Project Team: Assembling a team of internal experts tailored to your project’s specific needs.

- Specialized Project Management Tools: Utilizing tools designed to identify and formalize detailed client requirements.

- Flexibility and Anticipation: Demonstrating recognized adaptability and foresight to meet overall project demands.

- Adaptability: Adjusting to both project-specific and client-specific constraints to deliver optimal results.

Our goal is to ensure your project’s success by aligning our expertise with your vision.

We specialize in Biologics in Jura, Switzerland

With more than 6,000 sqm of facilities and more than 25 years of experience, Adragos Jura offers customized clinical manufacturing to support your therapeutic trials.

Meet our experts

Highly skilled and well-trained scientists specialized on all the steps of clinical manufacturing.

Adragos Hub

Find out more about Clinical Manufacturing in our recent blog posts.

Frequently Asked Questions

What is GMP clinical manufacturing?

Good Manufacturing Practice (GMP) clinical manufacturing involves the production of pharmaceutical products in a controlled and regulated environment to ensure quality and compliance with regulations. This process is designed for the production of clinical trial materials used to test the safety and efficacy of new drugs before they are approved for market release.

What are the 4 drug manufacturing activities?

The four primary activities in drug manufacturing are:

- Synthesis/Production: Creating the active pharmaceutical ingredients.

- Formulation: Combining the active ingredients with other substances to form the final medicinal product.

- Filling and Packaging: Filling the drug into its final form (e.g., tablets, capsules) and packaging it for distribution.

- Quality Control and Assurance: Testing and ensuring that the product meets the required standards and specifications.

What is clinical material?

Clinical material refers to the pharmaceutical products manufactured under GMP conditions intended for use in clinical trials. These materials are produced to test the efficacy and safety of drugs in human subjects.

What are the 5 P’s of GMP?

The 5 P’s of GMP are key principles aimed at ensuring product quality and compliance in pharmaceutical manufacturing:

- Procedures: Documentation and standard operating procedures must be followed rigorously.

- People: Ensuring that everyone involved is qualified and trained.

- Premises: Facilities must be designed and maintained to suit the manufacturing operations.

- Processes: All manufacturing processes must be clearly defined and controlled.

- Products: Products should be produced consistently within quality specifications.

What is the difference between GLP and GMP manufacturing?

GLP (Good Laboratory Practice) and GMP differ in their focus and application. GLP governs non-clinical laboratory studies that support research or marketing permits for products regulated by the government, focusing on the integrity of the data and the testing process. GMP, on the other hand, covers the manufacturing process, ensuring products are consistently produced and controlled according to quality standards for their intended use.

What is the difference between GMP and clinical grade?

GMP refers to the regulatory guidelines for manufacturing, which include clinical-grade products. Clinical grade usually indicates products used in clinical trials that meet GMP standards, highlighting their safety and quality for human use.