Leipzig, Germany

Our manufacturing facility in Leipzig specialises in semi-solid and non-sterile liquid pharmaceuticals. With over 100 years of experience, we have a track record of providing first class service and customer focused manufacturing.

Our Expertise

Semi-solids

Dosage Form

Creams, gels, ointments, healing paste

Formulation

Batch size: 15l – 1,250l

Packaging

Aluminum tubes: 2g –150g; Plastic tubes: 25g – 200g

Technologies

2 production lines: Marchesini and Norden

Non-Sterile Liquids

Dosage Form

Solutions, drops, suspension, emulsion

Formulation

Batch size: up to 4,000 liters

Packaging

Plastic and glass bottles: 20ml – 700ml

Technologies

3 production lines: Dovema, Groninger and Würschum

Our Services

Technology for Manufacturing

- Becomix 1200 liter

- Becomix 250 liter

- Becomix 15 liter

- Multi-Homo 500 liter

- EKATO-Mixer 4000 liter

Stability Testing

- Stability testing for climate area II, IVa and IVb

- Alarm-controlled monitoring of temperature and humidity

- Computer aided time schedule and data control

- Stability tests during clinical development and marketing stage

Quality Assurance

- To adhere with highest standards of quality and safety, we accomplish with regulatory standards, like:

- National/ EU (Landesdirektion Sachsen), In the realm of medicine quality.

- Manufacturing processes conducted under the strict overview of the AMG (Arzneimittelgesetz).

- GMP certification for both human and animal products.

- We measure quality assurance of cosmetics and food supplements, by the Veterinär- und Lebensmittelaufsichtsamt certificate.

Certifications

- QA committee

- Risk-based Qualification

- Supplier evaluation

- PQRs ( Product Quality Reviews )

- Yearly QMR (Quality Management Reviews)

- Self-inspections und auditing

- Risk-based cross-contamination management

- Paper based documentation system

- Validated software: ERP-GUS; Perfact; Seritrack

Quality Control Process

Routine-analytics

- Raw material analysis (active ingredients, auxiliary materials)

- Bulk goods and product analysis

- Batch release testing of solid, liquid & all kind of semisolid formulations

- Stability testing

- Investigation of residual solvents

Microbiology

- Microbiology tests of APIs and products (non-sterile)

- Bacterial counts (TAMC & TYMC)

Method development and validation

- Development of analytical methods and validation (HPLC, GC, GC-headspace, UV-VIS, titration)

- Design of dissolution models

- Development of cleaning validation methods

- Planning and execution of method transfers

Download Our Brochure Now!

We have prepared a brochure to help you discover our facility in Leipzig.

Key Information

Location: Leipzig, Germany

SQM: 13,300 m²

Foundation Year: 1,926

FTE (Employees): 120

Certifications

• Serialization according to EU FMD (European Union Falsified Medicines Directives)

• Manufacturing permission according to AMG

• EU GMP – Certification (human- & animal products)

Expertise

• Galenical development and transfer management

• Pilot batches

• Worldwide procurement of raw materials

• Production & Packaging

• Analytic and batch release/method transfer

• Stability studies and contract analysis

• Validation/product quality reviews

• Clinical investigational medicinal products

• Creation of product quality reviews

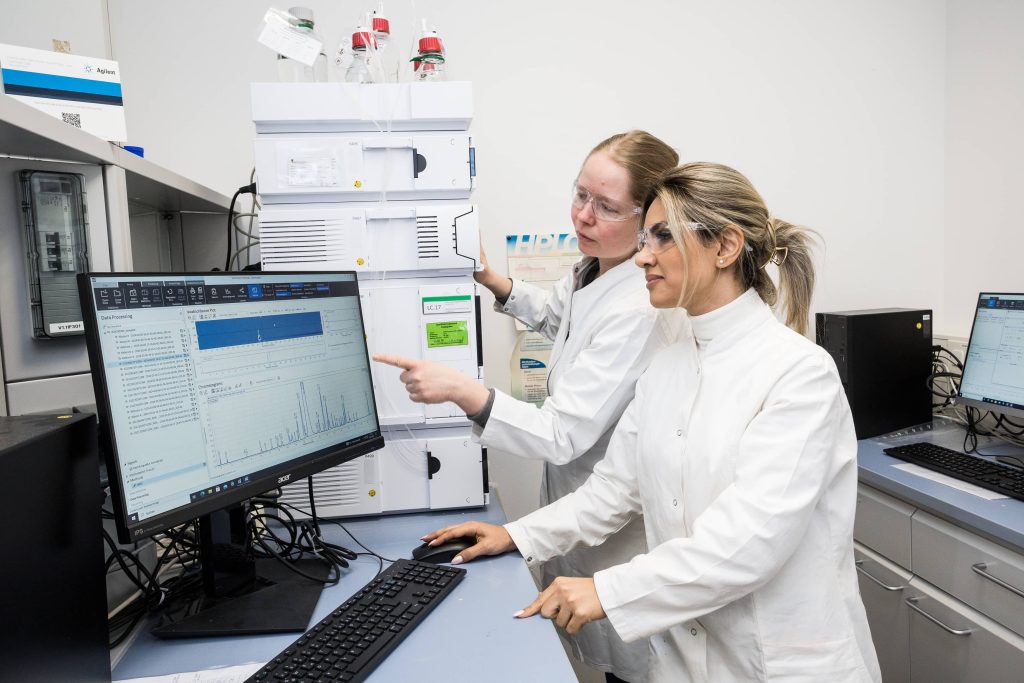

Meet our team in Leipzig

Highly skilled and experienced in their field.

Meet our Site Head

Florian Prell

With a career spanning over two decades in the pharmaceutical and packaging industries, Florian Prell is the new Site Head of Leipzig. A dedicated and results-driven professional, Florian has consistently demonstrated his ability to lead and optimize operations in highly demanding environments.

Florian’s journey through various key positions has equipped him with a comprehensive understanding of plant operations and process optimization. His leadership experience highlights his capability to manage complex, multi-faceted operations while ensuring efficiency and high standards in production.

Latest Articles

Read more about what’s happening at Adragos Leipzig.